Weighing Isolator I Containment Isolator

Description

- Dual-chamber weighing isolator

- Airlock with one glove allowing for loading of material and instruments

- Working chamber with three gloves intended for work with hazardous materials

- Possible to ensure inert atmosphere inside chambers (N2, Ar)

- Leak tightness class 3 according to ISO 10648-2

- “C” Class cleanliness according to EU GMP standard

- “Audit Trail” compliant

- Electronic control system for automatic adjustment of basic operating modes managed by Siemens PLC

- Color touchscreen controls

- Jacket material: stainless steel AISI 304

- Isolator working chamber material – AISI 316L with a thickness of 3.00 mm

- Polished surface finish, Ra < 0.6 µm

- Inlet filtration HEPA H14 - “C” Class cleanliness

- Safe filtration of exhaust air with double HEPA H14 filters

- Easy-to-clean inner and outer surfaces

- Sliding trays between chambers for easy material transfer

- Oval holes with gloves for improved material handling

- Turbulent flow

- Negative pressure mode

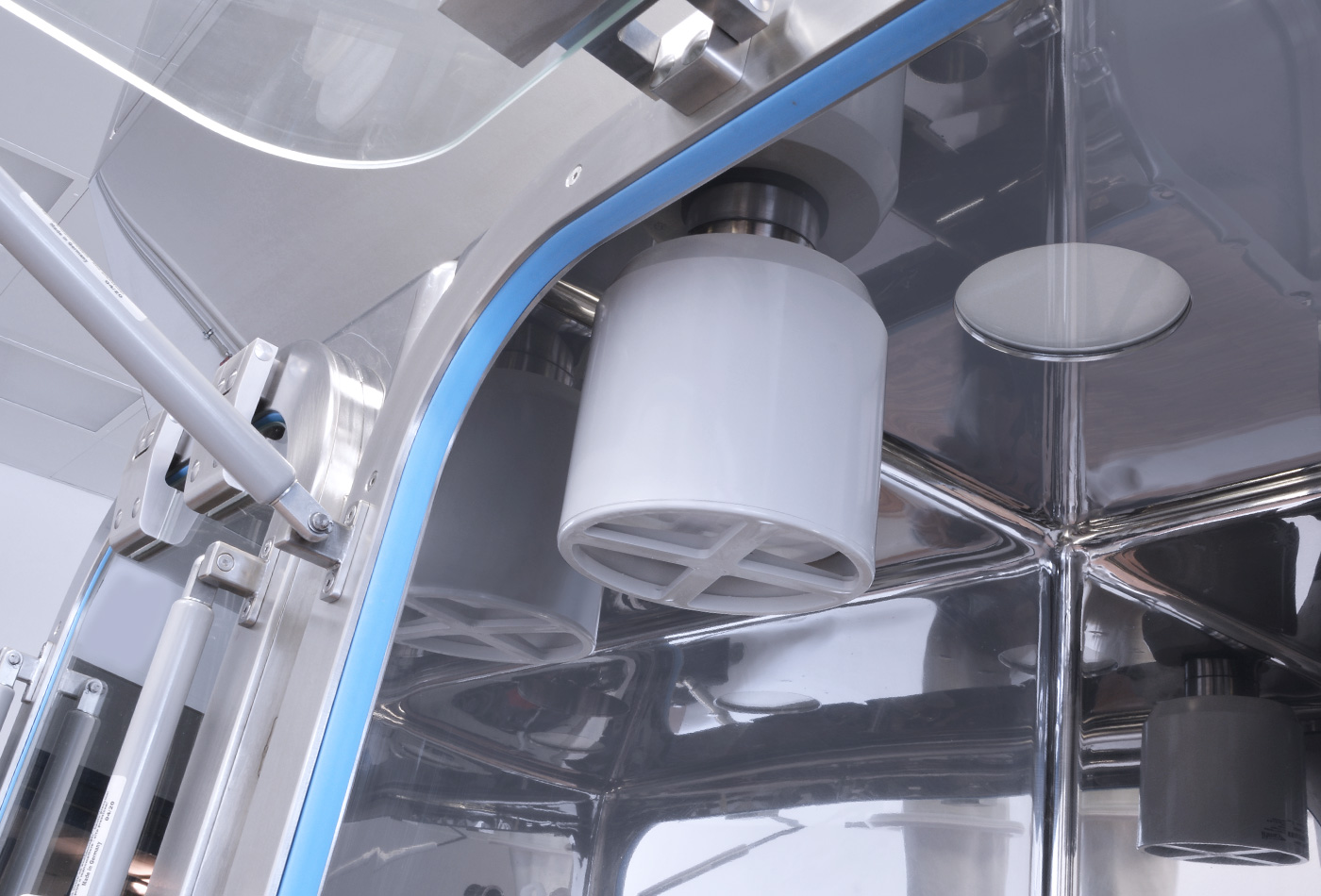

Turbulent Flow

Commonly used for “C” and “D” classes of cleanliness where the direction of airflow is not clearly defined. The air flows in an irregular direction from the air supply inlet to the air outlet through cylindrical HEPA filters H14 at a filtering efficiency of 99.995%. The rate of air exchanges of clean air into the chamber usually ranges from 5 to 40 exchanges per hour.

Negative Pressure

The HVAC system allows for the formation of negative pressure in the interior of the isolator. This function is mostly used in case of a failure – compromised leak-proofness - and helps to protect personnel.

Another level of protection for critical points in the process is the creation of a pressure cascade so that the location of dangerous substance handling contains the highest level of negative pressure. This minimizes the risk of contaminating other chambers or the surroundings.

In order to prevent damage to the equipment caused by insufficient pressure a pneumatic valve is used. This protective function prevents the pressure from dropping further, thus protecting the technology from damage.

Parts

- Visual and acoustic alarm

- HMI panel

- Working chamber K1

- Working chamber K2

- Main switch

- Hinged door

- Tri-clamp validation port

- F5 Pre-filter

- Liquid waste removal valve

- Tri clamp equipped for a continuous liner

- Front window

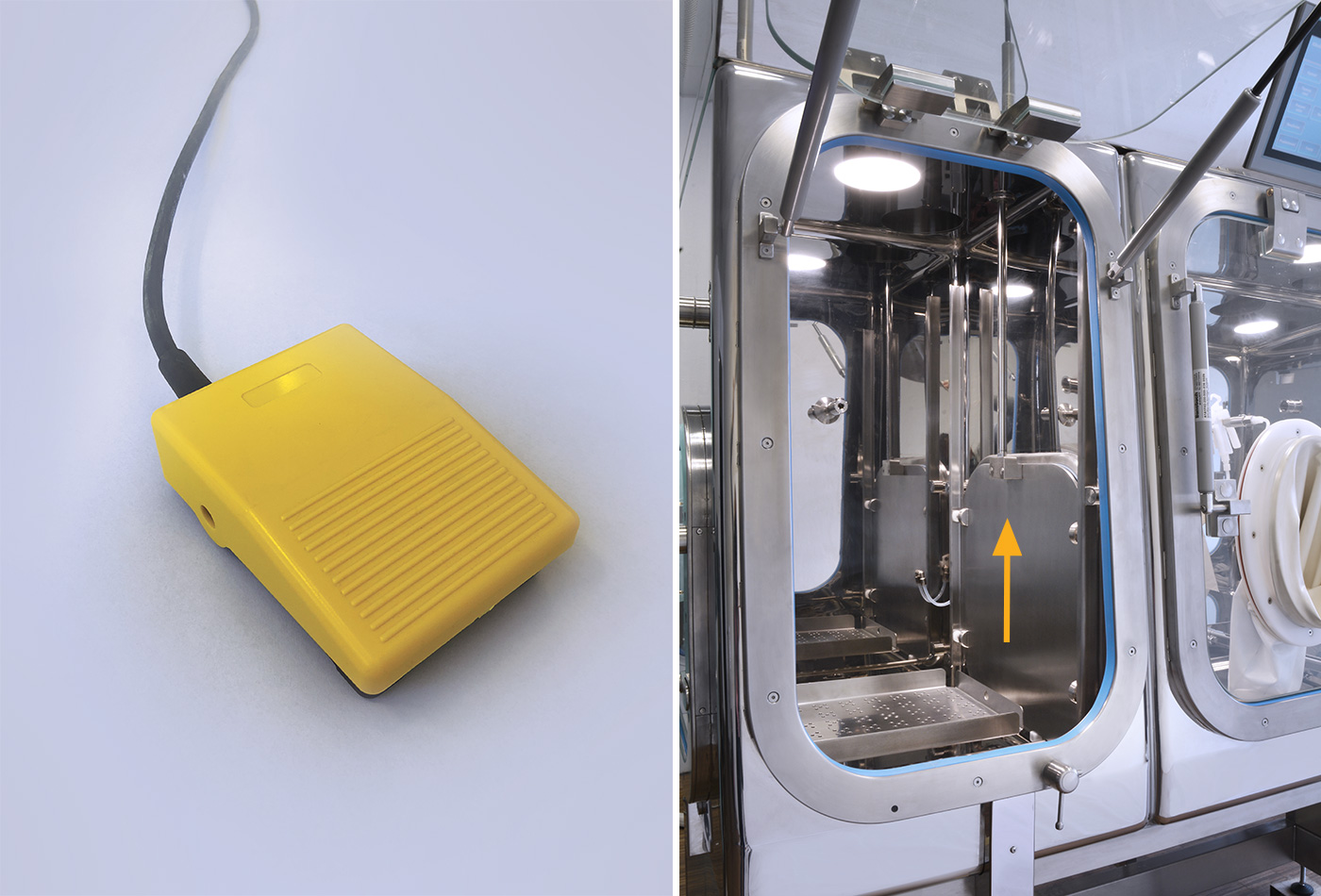

- Foot-operated switch

- Service panel

- Sensors for monitoring safe closure of the window

Standards

Visual and acoustic alarm

A beacon light and an acoustic alarm providing a quick audible and visual assessment of operational and failure states for the user.

Hinged door

The door allows for material transfer from the chamber to the surroundings or from the chamber to other equipment (e.g. a fume hood). The hinged door is operated with the help of a door latching mechanism. The door is made from AISI 316L stainless steel, safety glass, and silicone sealant.

Tri-clamp validation port

This tri-clamp is necessary for validation and a periodic re-validation process. Can be used as an input for sensors or other devices.

Valve for removing liquid waste from the chamber

Tri-clamp connection for an optional connection to the building waste pipe system or to add a collecting container.

Front window

Inflatable sealing, safety glass fitted with sleeved flanges. Sensors for monitoring safe window closure. A gas spring assists with easy opening.

Foot-operated switch

The foot-operated switch acts to control a sliding port between chambers. After material-transfer the port can be closed with the foot switch and there is no need to remove hands from the sleeves.

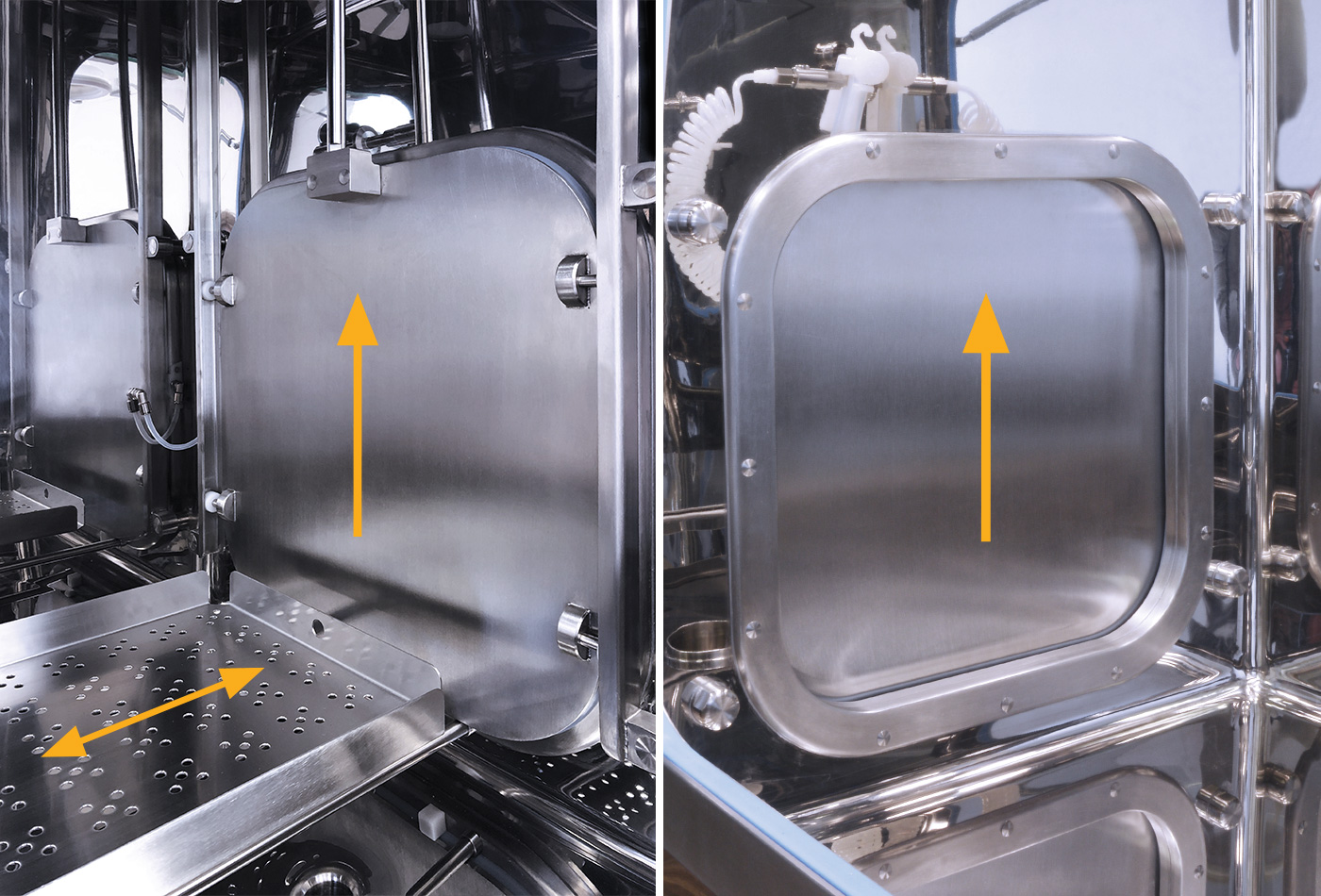

Sliding door and Sliding trays

The door allows material transfer between chambers. It is operated with a foot switch or with a control touch display. Door action is performed by a pneumatic valve. The door is fitted with inflatable sealing.

Sliding door and Sliding trays

For improved ergonomics and easy transfer of material, the airlock is fitted with a sliding tray.

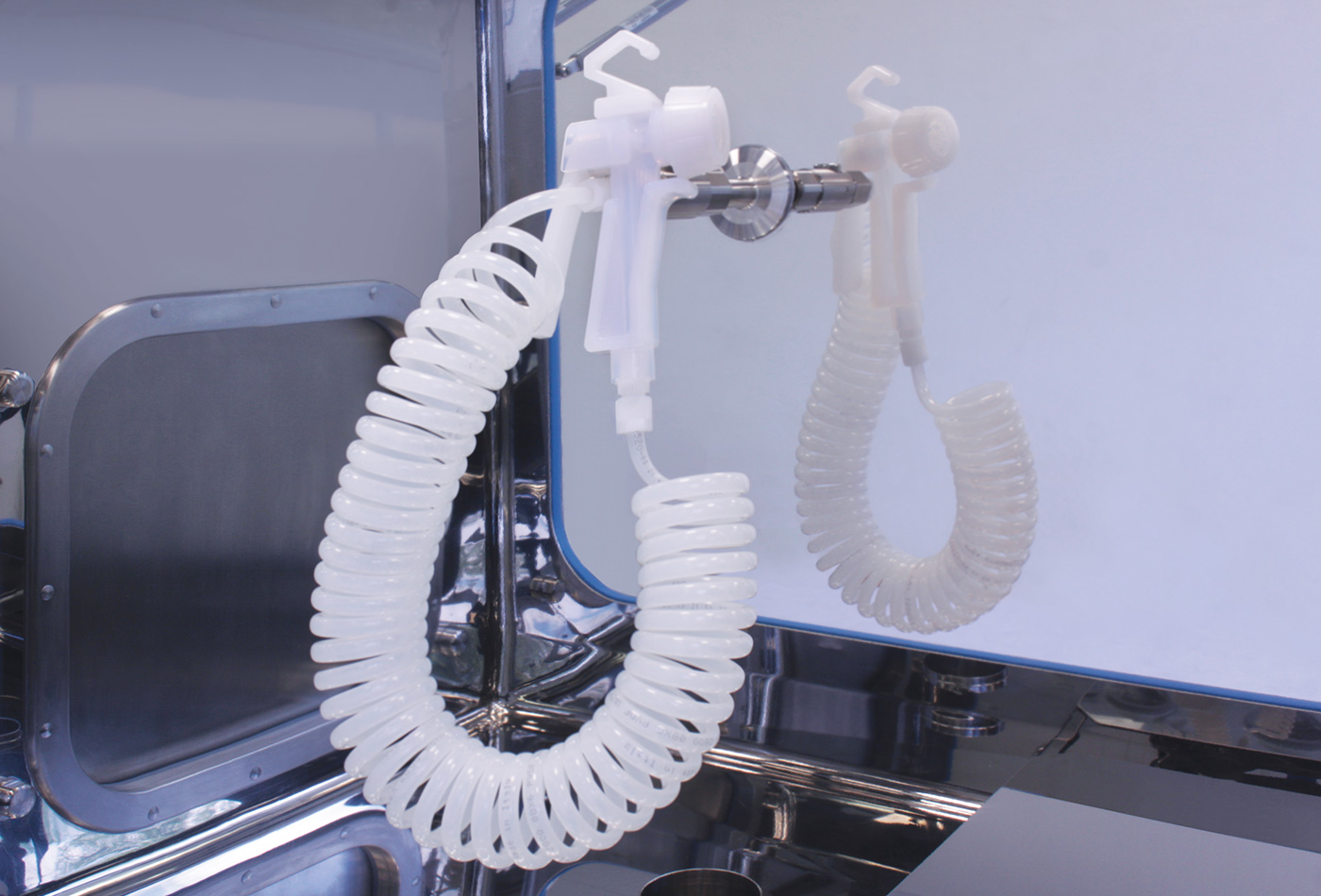

Shower

Easy cleaning of the isolator is made possible with an installed spray gun. It operates with two media and is controlled by a valve via the HMI panel. For washing, the chamber is connected to water piping and dried by switching over to compressed air.

Weighing platform

Optional integration of a weighing platform in the isolator —A solid stable shelf made from thick sheet metal provides a base for installation of a weighing device.

HEPA filters

Highly efficient H14 filters remove ultra-fine impurities from the air in the inlet and the outlet.

Rounded edges/corners inside the working chamber

Rounded corners and highly polished surfaces allow for easy cleaning of the chamber. The chambers are precision-welded which guarantees their leak tightness.

Tri clamp equipped for a continuous liner

Tri clamp equipped for a continuous liner.

Nekk

Optional mounting of a continuous liner for material removal. A continuous liner is used to transfer material out of the chamber without contaminating the operator. There is a swivel-closing mechanism inside the chamber. A tube projects outside the chamber protected by a tubular foil and is used for removal of material.

Standards

- Cable glands

- Cable glands are mounted in the isolator wall.

- Sockets for additional equipment power supply

- Sockets are placed on the isolator rear wall.

- Sockets are operable from the control display.

- Sockets available in all country variants.

- Wire trays & accessories

- The rear panel can be fitted with wire trays and hangers made of AISI 316L stainless steel.

- Built-in LED lights

- Built-in LED lights ensure illumination levels of at least of 500 lux.

Safety Features

- Pressure fuse

- The pressure fuse serves as a safety element indicating increased pressure in the chamber. In the event that the assigned pressure in the chamber is exceeded a pneumatic flap valve is opened and the pressure value is decreased without deterioration of internal atmosphere.

- Safety glass

- We use tempered safety glass for the front windows and ports of our equipment. This glass has improved mechanical properties and is durable. When damaged it forms small chunks which reduce the risk of injury from cuts.

- Safe replacement of sleeves

- Our glove / sleeve flanges have two grooves. The first for sealing the glove and the second for an o-ring. This design allows a standardised procedure for the safe replacement of gloves.

- Independent UPS power supply

- An independent UPS (Uninterruptible Power Supply) can be installed inside the isolator. In the event of an interruption in the supply of electricity, short-term operation is maintained through a power supply in the isolator to allow the process and the environment to be secured.

- Safe replacement of the main filter

Display

HMI Panel

This isolator control system is operated with a Siemens color touch screen. The Simatic control system from Siemens together with a foot-operated switch creates an intuitive and user-friendly experience. The screen displays the actual parameters of the environment and monitors emergency statuses. The system includes remote access for customer service support. As required, it is possible to implement connection to an additional device for production data storage and export.

Drawings

Weighing Isolator I Containment Isolator

Dimensions in mm - Weighing Isolator I Containment Isolator

| Width | 1900 |

| Height | 2550 |

| Front height | 1770 |

| Depth | 1000 |

| Working plate height | 820 |

| Glove position* | 1220* |

| Usable depth space | 650 |

* *Option to alter on request

Dimensions in mm - working chamber K1

| Width | 1350 |

| Depth | 650 |

| Height | 950 |

| K1 chamber total volume | 0,83 m3 |

Dimensions in mm - working chamber K2

| Width | 550 |

| Depth | 650 |

| Height | 950 |

| K2 chamber total volume | 0,34 m3 |

Download

Free download

| Name | Type | Availability | Size |

|---|---|---|---|

| Containment Weighing Isolator_EN_2021 | 6.54 MB | ||

| BLOCK Technology_Overview_EN | 2.3 MB | ||

| BLOCK Technology_Company Profile_EN | 11.84 MB |